Main Applications of W-Cu Composites

Main Applications of W-Cu Composites

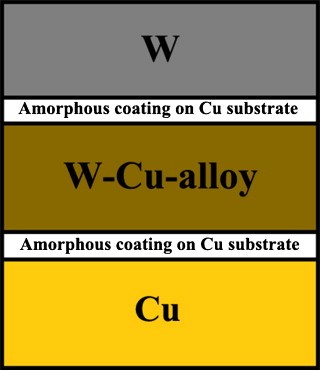

Tungsten has high hardness and the highest melting point among all metals, copper (Cu) has excellent electrical and thermal conductivity, while the W-Cu composite has good electrical and thermal conductivity, low thermal expansion coefficient and high resistance to arc corrosion, so they have been widely used as electric contacts, EDM, resistance welding and plasma electrode materials for a long time. With the development of microelectronic information technology, W-Cu composite material has been widely used in large-scale integrated circuits and high power microwave devices.

W-Cu composite material used for electrical contact

Due to the melting point of W (3390 ~ 3430 ℃) is much higher than the boiling point of Cu (2350 ~ 2600 ℃),The W-Cu composite material has excellent resistance to arc corrosion, fusion welding, and voltage resistance, making it especially suitable for use as high voltage and UHV open and close contacts.

W-Cu composite for electronic packaging and heat sink

The W-Cu composite material is easy to adjust the thermo-physical parameters and greatly improves its application range in microelectronic devices. Therefore, it is regarded as a good heat sink material in high-power devices. The suitable thermal expansion coefficient can be well matched with semiconductor materials.

W-Cu composite material for electrode machining

The development of various advanced electro-machining technologies has also become another important application field of W-Cu composites with high heat resistance, high electrical conductivity, thermal conductivity, and arc ablation resistance.